Fundamentals of a High-Velocity Air Duct System

If you attended the Virtual Fall Technical Conference, you heard all about the fundamentals of high-velocity air duct systems from David Monson. If you missed it, you're in luck! We’re here to recap the session and provide valuable educational tools for any business performing HVAC system cleaning for these highly complex systems.

After reading this article, you will:

- Know how high-pressure systems relate to high-velocity systems.

- Know the components of high-velocity system designs.

- Know how to clean and troubleshoot cleaning high-velocity systems.

What is a high-velocity system? First, let’s talk about high-pressure vs. high-velocity systems. Professionals familiar with high-pressure systems may think that they are already aware of high-velocity systems. However, there are marked differences between these two systems.

For instance, which holds more air? Eleven 55-gallon drums or a single scuba tank? The answer: they hold just about the same. The difference between the two is pressure.

It takes a certain volume of air with particular heat content to do the heating and cooling functions in a building. If space is at a minimum in the building, how do you deliver the required volume of air? The answer is to pressurize it and deliver it through smaller ducts.

So, why is it called a high-velocity system instead of a high-pressure system? We can’t perceive pressure in an air duct with our senses, but we can perceive air velocity with our senses. Every high-pressure duct system is also a high-velocity duct system. When you increase the pressure in a duct system and run it through smaller ducts, you end up with high-velocity air.

Consumers choose high-velocity systems for a wide range of reasons. One key reason these systems may be favored is for their smaller footprint — construction costs are now calculated per cubic foot instead of per square foot, making installing high-velocity systems more affordable than in the past. Their smaller size also makes them ideal for discretely adding air conditioning to historic buildings.

While high-velocity systems may be preferred for cost, space, or other reasons, it’s important to note that the systems don’t do the work any better or any more reliably than conventional systems, they just deliver that work in a smaller space.

High-Velocity System Designs

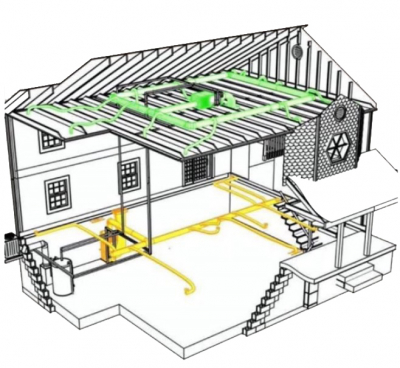

Figure 1 below shows an example of a home with a high-velocity system in an attic (shown in green). Items to note:

- The attic of the home has a loop system.

- An air handling unit is located in the center of the attic.

- The air handling unit delivers air out to a T junction on a main trunk duct loop that goes around the perimeter of the attic.

- Flex ducts extend off the loop, leading to diffusers.

- A perimeter loop system is used to equalize pressure at the connection point for every one of the branch ducts, ensuring the system is balanced.

Figure 1: A home with two types of high-velocity system installations.

The bottom of Figure 1 also shows the more traditional method that may be found in the basement level of homes with a conventional straight trunk with branch ducts (shown in yellow).

Return duct systems operate similarly to normal returns; one or two returns will be located in the central area, as opposed to having returned grills in every room. They tend to be short and simple and consist of standard ductwork because the fan is bringing return air back to the air handling unit as intended.

Supply trunk ducts in residential systems are usually 8-inch round ducts, though large systems may use 10-inch round duct. Generally, the supply trunk duct of a high-velocity system is very much like that of a typical branch duct on a conventional system.

All of the branch ducts, however, are specialized 2-inch insulated flex ducts designed to absorb sound — a major issue for customers who have high-velocity systems in their home. There are three main brands that sell these specialized flex ducts:

• Unico

• Hi-Velocity

• SpacePak

Some systems have sound-attenuating sections of flex duct that must be a minimum of 12 feet long. For longer runs, there is a perforated semi-rigid aluminum insulated duct that is two inches in diameter. No matter the length of the run, a minimum 12-foot-long sound-attenuating section must be present. Several brands also have a large assortment of brand-specific connectors, splices, and crimp fittings. One brand utilizes aluminum core duct for most of the branch runs, and have 2-foot-long sound-attenuating sections at the ends. Parts from different brands are not interchangeable.

High-velocity sound attenuation is the same principle as glass pack mufflers on a hot rod: there is an inner pipe that’s perforated with a blanket of sound insulation, and then an outer housing. The high-velocity frequencies go through the perforations into the insulation and the sound is absorbed by the insulation.

High-Velocity System Cleaning Techniques

Cleaning a high-velocity system has some differences and similarities to cleaning a conventional system. You clean the return the same way as a normal return, as well as the supply trunk. The flex duct used in high-velocity systems is the most challenging component of a high-velocity system to clean, as there are currently no special cleaning tools for two-inch diameter ducts. It’s possible to get cleaning equipment into the flex ducts, but it would be impossible to get it out.

This challenge is best illustrated by a case study about a house that had been dusted with ultra-fine pink terracotta dust from a failed HEPA vacuum. The house had three Unico high-velocity duct systems, and the pink dust infiltrated the two-inch flex ducts.

To successfully clean this duct system, every flex duct branch had to be disconnected and pulled straight, even in tight cubbyholes, so that cleaning equipment could pass through the branches and be retrieved after cleaning. It was possible to do this in the house, but it was a time-consuming and difficult process. These jobs must be estimated correctly from a time and effort standpoint, understanding that they take considerably more time and are much more difficult to accomplish at this point in time.

Conclusion

While high-velocity systems have yet to gain prevalence in some areas, duct cleaners should be prepared to deal with them. Conventional duct cleaning methods may not work well on these systems, and some methods will outright fail. There may also be some situations where standard cleaning practices will not meet customer expectations. In those cases, replacing the components is the only solution you can stand behind.

This Article is Eligible for Continuing Education Credits!

This article originally appeared in the March/April 2021 edition of DucTales. New this year — and available to members only — CECs required for ASCS certification renewal can be earned by simply reading a specific article in each edition of DucTales magazine, and then taking (and passing) a short quiz. This article is worth one (1) CEC. To earn your CEC, simply CLICK HERE, login, then purchase and complete the CE quiz.